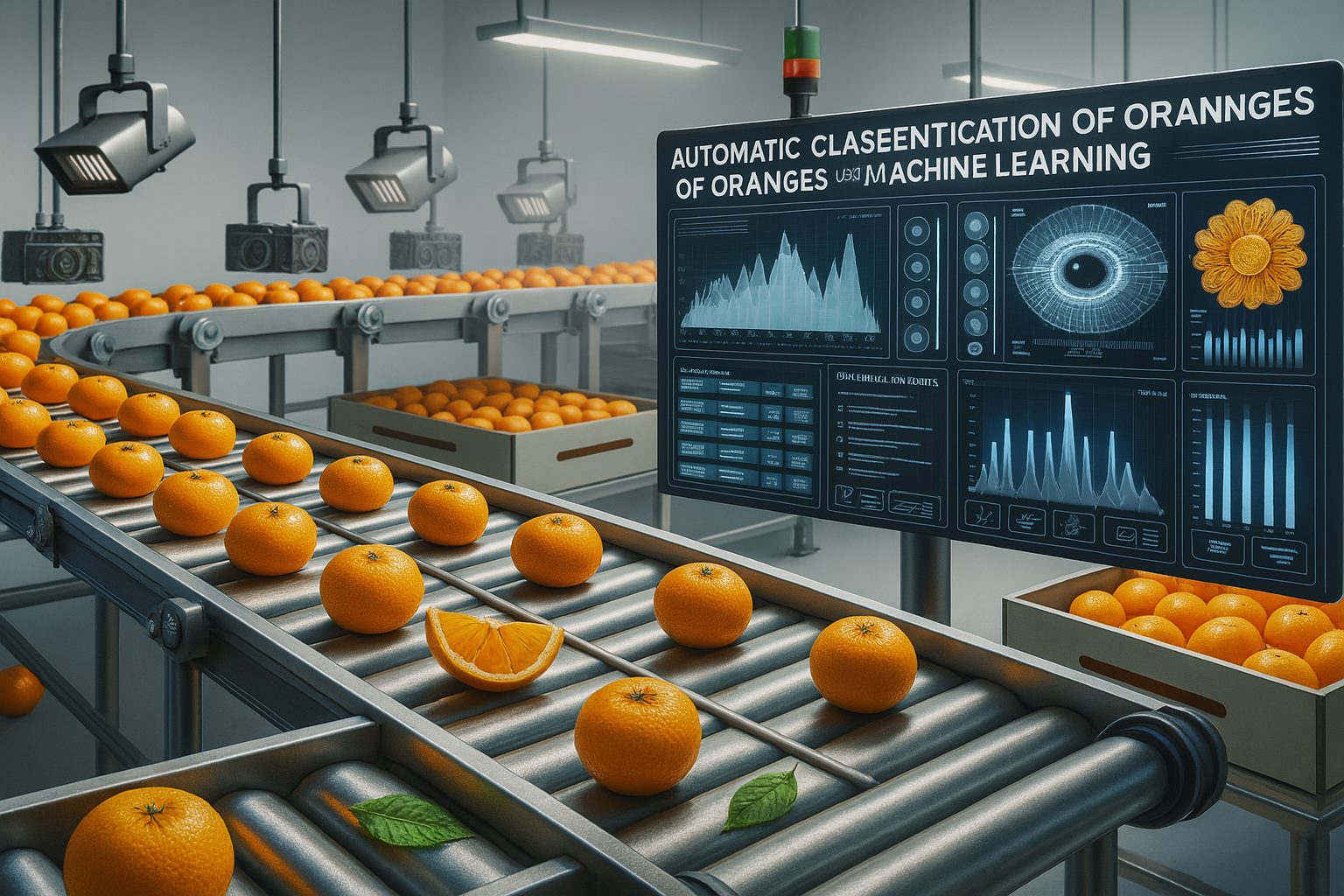

NKKTech Global has developed a smart agricultural trading platform that delivers an exceptional user experience, powered by its advanced machine learning–driven orange classification system. This intelligent feature automatically analyzes harvest images and sensor data to categorize oranges by size, color, and quality grade—helping buyers find the fruits that best suit their needs.

With a fast and intuitive interface, the platform eliminates manual sorting, streamlines the selection process, and enables users to browse, filter, and order produce confidently in seconds.

By leveraging cutting‑edge AI, IoT integration, and a scalable cloud architecture, NKKTech Global has set a new standard in smart agricultural commerce—boosting efficiency and satisfaction for both growers and buyers.